Featured Post

Lap Shear Strength To Swedis

- Get link

- X

- Other Apps

Adhesives Determination of tensile lap shear strength of. With a bonded area of 300 mm 2 this results in a calculated LSS of 233 MPa.

Structural Safety Evaluation Of Adhesive Bonds A Fracture Analytical Approach Sciencedirect

This is a great product for around the shop with steel to steel bonds of approx.

Lap shear strength to swedis. CS1 PCM bonded strongly to skin reaching. METHODS FOR TESTING PAINTS AND RELATED MATERIALS Caltrans. Several experiments were conducted on lap shear specimens using a universal testing machine and the results were used to ascertain optimum working conditions in order to achieve the maximum joint strength and to predict how the joint strength will vary if these conditions are altered.

Human translations with examples. DIN EN 1465 1995 01 Beuth de. MyMemory Worlds Largest Translation Memory.

Quality of the adherend surface. Tensile Lap Shear Strength Rigid to. The bonding strength of the proposed method was evaluated through lap shear strength and peel strength testing and 50 higher peel strength than hot compaction method while lap shear strength was.

The tensile lap shear strength and failure energy were observed to first increase with increasing welding energy reach the maximum values at 1500 J. Standard lap-joint single screw tests 83 standard lap-joint 2 screw tests 16 standard lap. They are the most widely used specimens.

Dublin County Dublin Ireland. Higher ten sile strength and lap shear strength. Deutlich ve rbesserte Zug- und Zugscherfestigkeit.

Strength values should be measured on clean surfaces. This process entails managing the development process for the contestable and non-contestable. The single-lap shear test is commonly used to determine the in situ strength of an adhesive by placing the adhesive between two plates and applying a load until failure.

Bonded lap shear specimen broken in the steel 1mm gauge. Darwis has 2 jobs listed on their profile. See the complete profile on LinkedIn and discover Darwis connections and jobs at similar companies.

3000PSI Lap Shear strength and the ability to attach dissimilar metals and plastics its. Comparison of the shear strength and DRS of single-lap joint specimens 22. The aim of the present study was to evaluate the soft tissue bond strength of a newly developed monomeric biomimetic tissue adhesive called phosphoserine modified cement PMC.

Surface preparation in series-type production must be similar to the test conditions if comparable results are to be achieved. The lap joint efficiency test results revealed that the highest lap shear strength was exhibited by GFRP-GFRP SLJ amounting to a value of 684 008 MPa. Cleaning then follows according to DIN 53281 sheet 1.

Results indicate a 10 increase in lap-shear strength and 75120 increase in work to failure for the IAJs compared to the BAJs at all loading rates. In addition to these control parameters a number of other process variables were recorded for each weld including weld time. The shear strength of screw connections in the North American Specification for the Design of.

Standard BSI BS ISO 4587 standards globalspec com. Working as a Senior Project Manager in the New Connections Team my target is to successfully manage a number of customer connection projects to the grid ranging from 40MW to 100MW. Untersch iede in der Festigkeit und Aushärt ezeit.

The joint deformation mechanisms are examined and fractography analysis is performed at the macro and micro scales. Lap joints are being made to measure tension-shear strength and to correlate strength with processing parameters and microstructures. Swedish Military Aircraft JAS Gripen 17 2 However there are various parameters that can affect the performance of an adhesive bond.

NOTE 1 Single-lap specimens are economical practical and easy to make. Spot-welds were made by varying the parameters of tool plunge depth and tool plunging rate. Shear is typically tested using a single- or double-lap shear test as shown in Fig.

The third source of screw shear data was from a report to the Swedish Building Research Institute Berggren et al. Coordinated the team during fabrication and testing of Adhesively Bonded Single Lap Joint composite specimens Evaluated the lap shear strength of specimens fabricated with different bonding pressures Presented the optimum bonding pressure results and methods to industry. Assuming a yield strength of 280 MPa thickness of 10 mm and width of 25 mm the yield stress will be 7000 kN.

Lap shear strength testing measures the ability of a material to withstand stresses set in a plane where the exerted shear force is moving the two substrates in opposite directions. Show more Show less. Two types of PMCs were evaluated using lap shear strength LSS testing on porcine skin.

View Darwis Japs profile on LinkedIn the worlds largest professional community. In addition to these control parameters a number of other process variables will be recorded for each weld. Adhesive lap-shear bond strength is determined by stressing a single-overlap joint between rigid adherends in shear by the application of a tensile force parallel to the bond area and to the major axis of the specimen.

A decrement of 1098 and 3317 was. It is one of the most common stresses that a bonded joint can face during service especially in structural bonding applications. The spot welds will be made by varying the parameters of tool plunge depth and tool-plunging rate.

Testing the same adhesive according to DIN 54451 often gives an LSS of more than 40 MPa but. Decrease of the lap shear strength in t he wet state. The ISO 4587 Toolkit store theartofservice com.

Microhardness and grain size were established. Rückgan g der Zugscherfestigkeit im na ssen Zustand. In this investigation sandwich and laminate single lap-shear specimens were manufactured in cold ambient and hot environments using five typical adhesives commonly used for bonded repairs conducted in the field.

They are as given below. -Effect of bonding time after mixing on joint strength. ISO 4587 Tensile Lap Shear Strength of Rigid to Rigid.

The lap shear strength and failure energy of the welds first increased and then decreased with increasing welding energy with the maximum lap shear strength and failure energy occurring at 1250 J. Lap shears used for shear strength measurements are blasted with special alumina 70 grain. Lap joints were made to measure tension-shear strength and to correlate strength with processing parameters and microstructures.

The use of these adhesives in these environments and resulting mechanical strength of repair were evaluated. Contextual translation of lap shear strength into Italian. Apr 2021 - Present6 months.

A calcium metasilicate CS1 and alpha tricalcium phosphate TCP PMC.

Phs Automotive Applications And Usage Ahss Guidelines

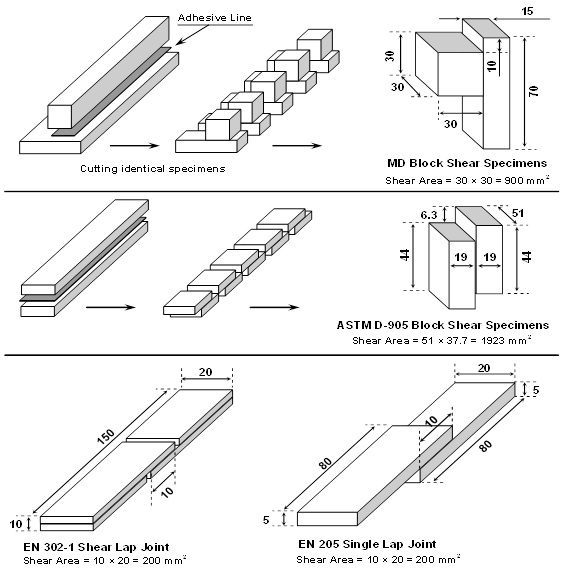

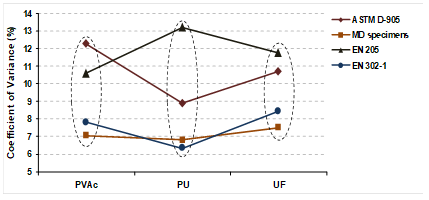

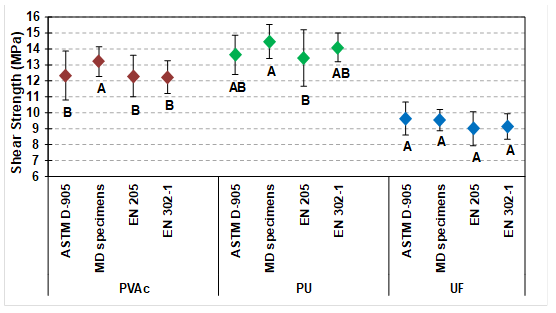

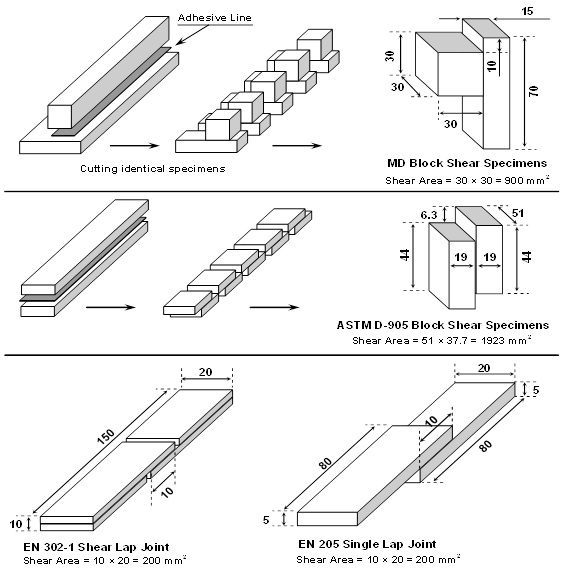

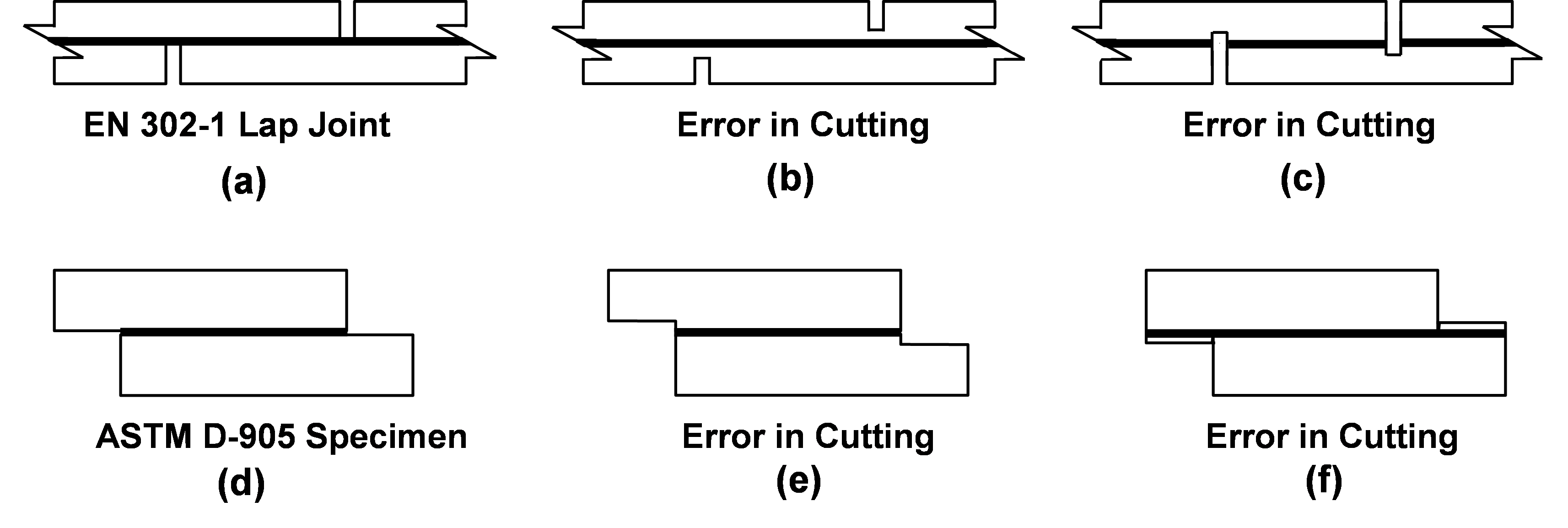

A Modified Method For Shear Strength Measurement Of Adhesive Bonds In Solid Wood Bioresources

Adhesion Performance Of The Bioadhesive Hydrogel Family A Adhesion Download Scientific Diagram

The Effect Of Pin Plunge Depth And Fluted Pin Design On The Lap Shear Download Scientific Diagram

Schematic Illustration Of Lap Shear Adhesive Bonding For P Vgal Download Scientific Diagram

An Intrinsically Adhesive Family Of Injectable And Photo Curable Hydrogels With Functional Physicochemical Performance For Regenerative Medicine Karami 2021 Macromolecular Rapid Communications Wiley Online Library

A Modified Method For Shear Strength Measurement Of Adhesive Bonds In Solid Wood Bioresources

Strength Of Laps And Anchorages Of Plain Surface Bars Cairns 2018 Structural Concrete Wiley Online Library

Hybrid Welding Procedures Ahss Guidelines

Pdf Shear Strength And Durability Testing Of Adhesive Bonds In Cross Laminated Timber

A Modified Method For Shear Strength Measurement Of Adhesive Bonds In Solid Wood Bioresources

Hybrid Welding Procedures Ahss Guidelines

A Modified Method For Shear Strength Measurement Of Adhesive Bonds In Solid Wood Bioresources

Hybrid Welding Procedures Ahss Guidelines

Tensile Properties And Interfacial Shear Strength Of Recycled Fibers From Wind Turbine Waste Sciencedirect

Phs Simulation Ahss Guidelines

Strength Of Laps And Anchorages Of Plain Surface Bars Cairns 2018 Structural Concrete Wiley Online Library

Comments

Post a Comment